Delta Circuits provides a complete one-source solution to your manufacturing requirements through our comprehensive... changing demands of the electronic industries latest technologies.

RF (Radio Frequency Boards)

- Top to Bottom Alignment .0005" Same Layers

- Etching ±.0005" (1/2 Oz. Copper)

- .001" Spacing

- Measuring Capability for Coupling, Filters, Impendance, Differential Pair measurements in house

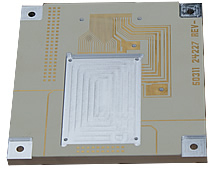

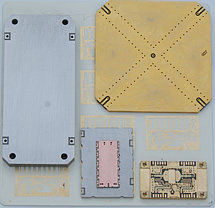

Power Amplifier Boards

- Mix Dielectric Multilayer

- Highly Thermally Conductive Materials

- Cavity under Power transistor launch area for RF Ground and edge plating

- Selective Plating

- Selective Edge Plating

Conductive Thermal or Electrical Adhesive

- 2-5 mil Thickness Conductive adhesive

- Selectively Applied Adhesive

- Pre cut or Pre Forms

- Post and Pre fab after attachment

- Vertical Machining Center Capability

- DC Resistance measurement Capability

Sweat Soldering

- Temperature range from 165 deg C- 290 deg C Solder.

- Selectively Specified area to be attached.

- Complex Board connection with metal carrier.

- Metal Coins at power transistor area.

- Metal back board attached to base plate.

High Count Layers Ceramic filled Multilayer Boards (Certified MIL-PRF-55110,Type 3)

- 36 Layers Ceramic filled multilayer

- Homogeneous Prepreg

- Precise Layer to Layer Registration

- X-ray measurement Capability for layer movement and layer to layer registration.

Fusion Bonding

- 24 Layers Teflon Fusion Bonding Capability (24" X 24")

- Same Dielectric Constant and Material Properties since fusing the same material as core.

- Good Control with material movement in X,Y & Z directions.

FEP Bonding

- Pure FEP Bonding , Very low loss .0002

- Excellent at high frequency

High Power RF Component Boards

- Up to 0.500" thick multilayer boards

- Cavity to middle layer for RF Connection

- Hole Castellation

- Selective Edge plating for RF Grounding

Printed Antenna on Multilayer Boards

- ±.0005" Line Width Tolerances.

- ± .0005" Spacing Tolerances

- Cavity mount for Circulators.

- Single Side 36" X 100" largest Size board

Back Plane

- Double and Multilayer largest board size 30" X 52"

- Back Plane Layers up to 48

- Largest board size 30" X 52"

- Aspect Ratio of 18:1

Microvia

- Smallest Platted vias 1.9 mil (Laser or Mechanical drilling)

- Via Filled with Non Conductive and Conductive Epoxy

- Vial Plate and Shut.

- Via in Pad with Caps

- 18:1 Aspect Ratio Panel to Drill(Pulse Plating Rectifier)

Blind /Buried Vias

- Blind, Buried vias and Blind/Buried Vias

- Sequential Lamination

- Depth Control drilling/Laser depth control 1:1 Ratio

- Mix Dielectric: Combination of Teflon, Getek, Rogers Duroid 4350, Nelco 400, NL 2000, FR 406 & 408 & many more

- Selective to pocket depth in layers for immediate RF ground for power transistor or metal slugs.

BGA

- 20 mil ball grid array

- 100% electrical testing with Flying Probe or Electrical Fixture.

- With Via in Pad

- With micro vias.

Surface Finisher

- Electroless Nickel and Immersion Gold

- Immersion Tin

- HASL,OSP,Virgin Tin,Bare Copper

- Wire Bondable Gold

Rigid /Flex

- Flex

- Flex Multilayer

- Rigid/Flex

Thin Laminates

- 0.002"- .005"

- Critical Geometry

Single Side Antenna Boards

- up to 96" long board

MEDICAL

AEROSPACE

COMPUTING